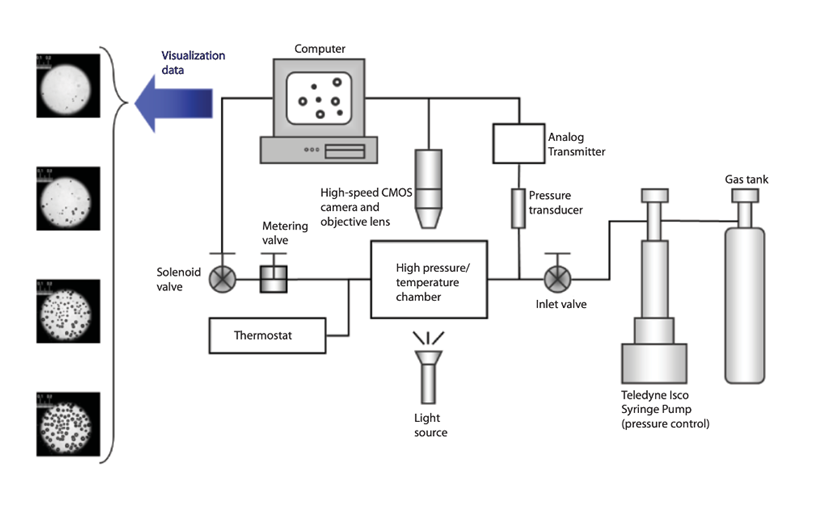

Plastic Foaming Simulation System Using Taledyne Isco Syringe Pumps

The pressure inside the chamber is one of the system’s most important experimental parameters for this system. To be specific, it determines the amount of gas that dissolves in the plastic sample and influences the pressure drop rate inside the chamber when gas is released to the surroundings to initiate foaming. Both the gas content and the pressure drop rate were shown to be significant factors for foaming in the previous research; hence, it is very important that the pres- sure inside the chamber be controlled as accurately and precisely as possible.

The Teledyne Isco Syringe Pump supplies gas at a constant pressure inside the chamber. The pressure used in the foaming experiments is normally within the range of 300 to 3,000 psi, well within the capability of the syringe pump. As mentioned previously, for each experi- ment, the gas pressure is to be maintained at the set level for approximately 30 minutes to allow the gas to be completely dissolved into the polymer sampler before the gas release. During that time, the gas pressure must be accurately maintained at the set level, with minimal fluctuation, because any instability in gas pressure can potentially cause premature foaming inside the plastic sample, which undermines the validity of the experi- mental results.