【ISCO】AN25 _ 漿料攪拌及懸浮液應用 (SlurryMixer Particle Suspension)

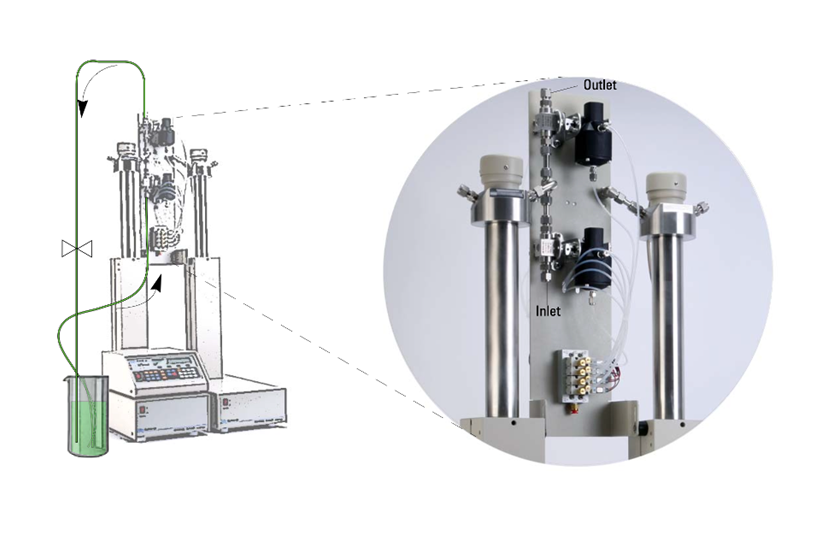

A 20% weight-weight combination of cornstarch and water was drawn into the syringe pump cylinder and mixed with the slurry mixer apparatus.

A 20% weight-weight combination of cornstarch and water was drawn into the syringe pump cylinder and mixed with the slurry mixer apparatus.

In the laboratory at Teledyne Isco, Inc., slurry mix- tures with specific weight-weight ratios were pumped through a Teledyne Isco Syringe Pump system in order to determine what degrees of slurry thickness could be pumped with an Isco pump.

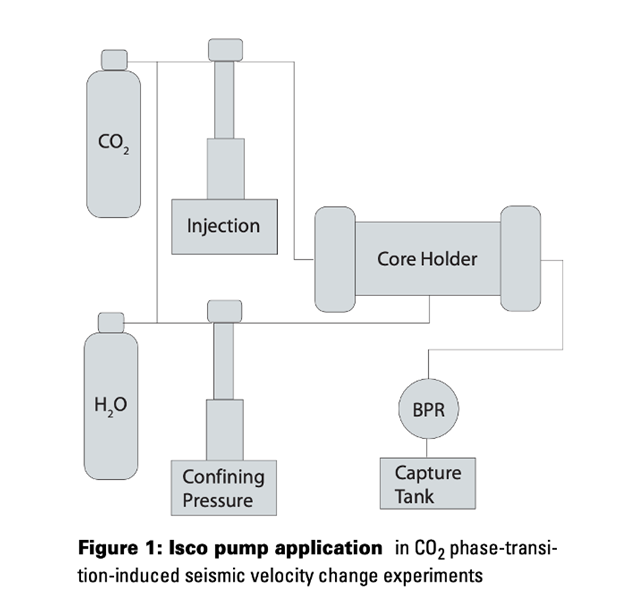

Both CO₂-based enhanced oil recovery (EOR) and CO₂ geological sequestration involve injecting CO₂ into deep rocks.

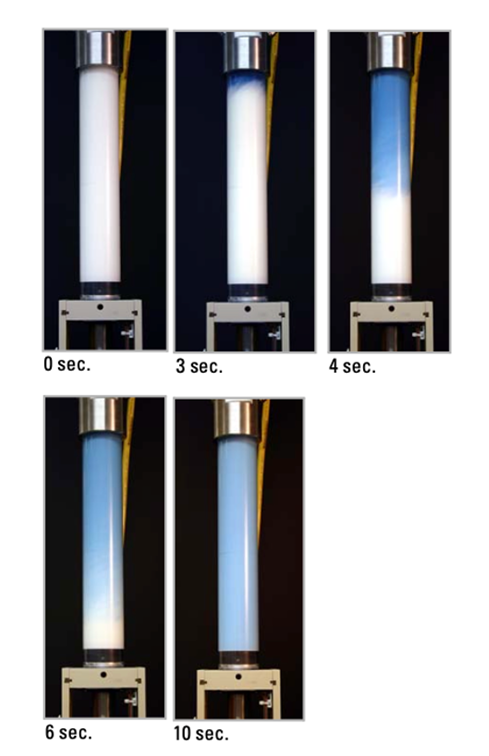

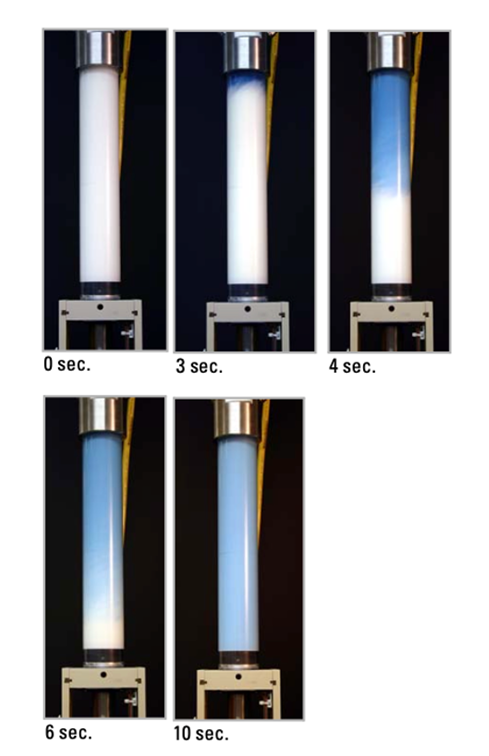

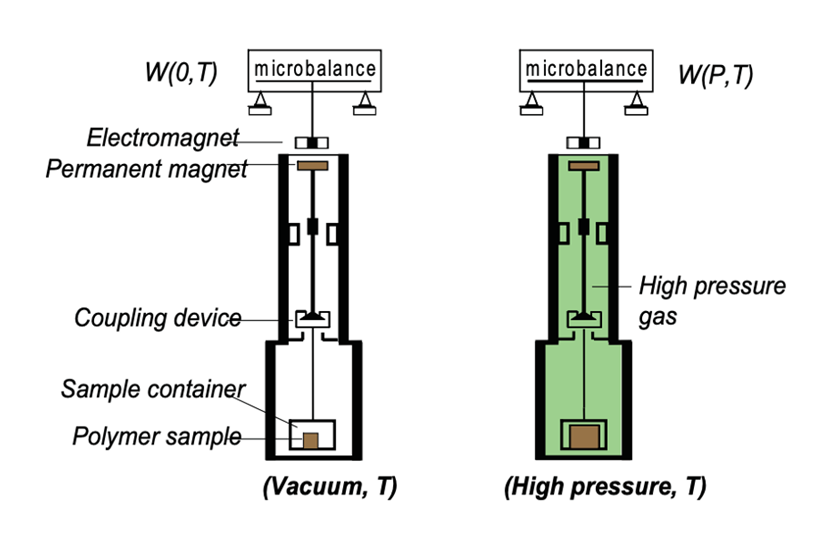

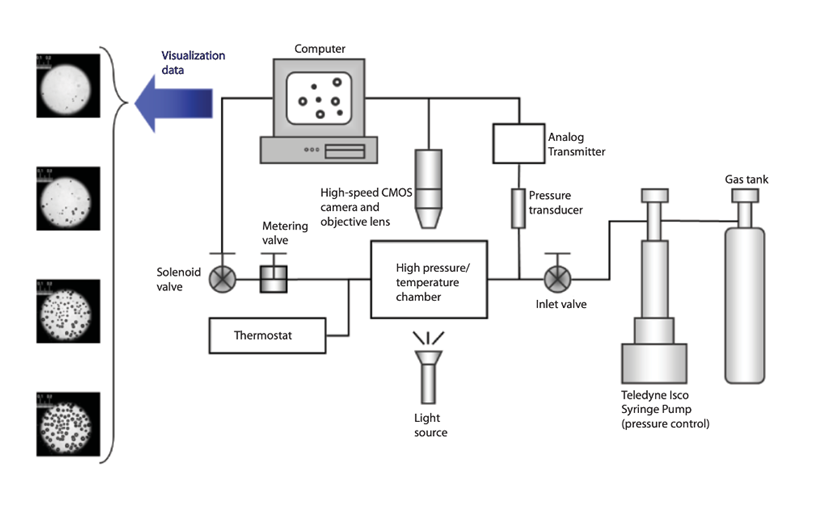

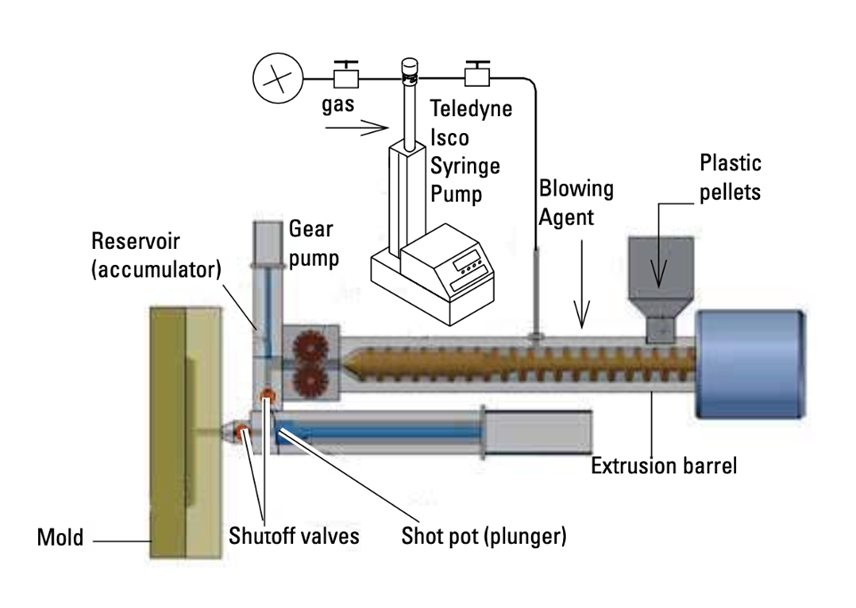

The solubility of physical blowing agents plays a key role in the manufacturing of plastic foams. This solu- bility study aims to investigate the amount of gas that can dissolve in polymer melt at a given temperature and pressure.

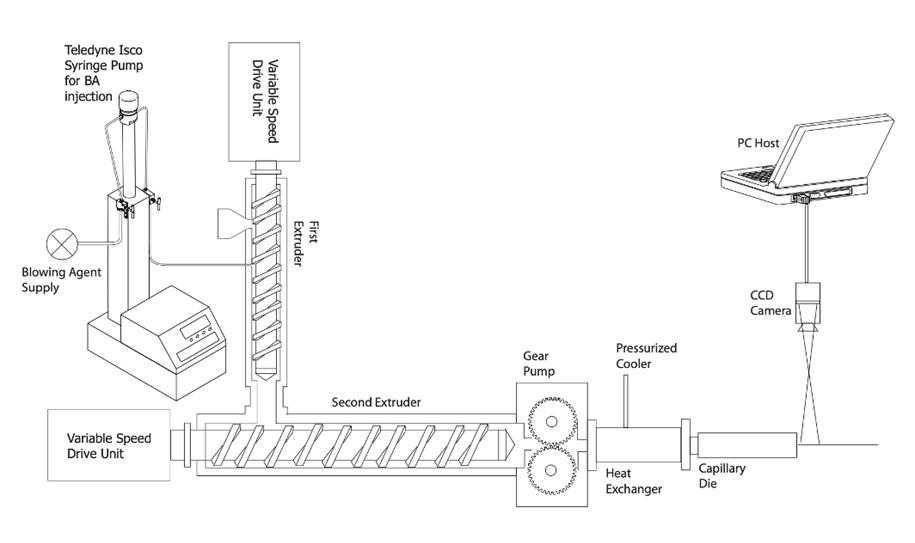

Extrusion foaming for the production of medium- and low-density thermoplastic foams has been carried out successfully for some time with physical blowing agents (PBAs).

To be specific, it determines the amount of gas that dissolves in the plastic sample and influences the pressure drop rate inside the chamber when gas is released to the surroundings to initiate foaming.

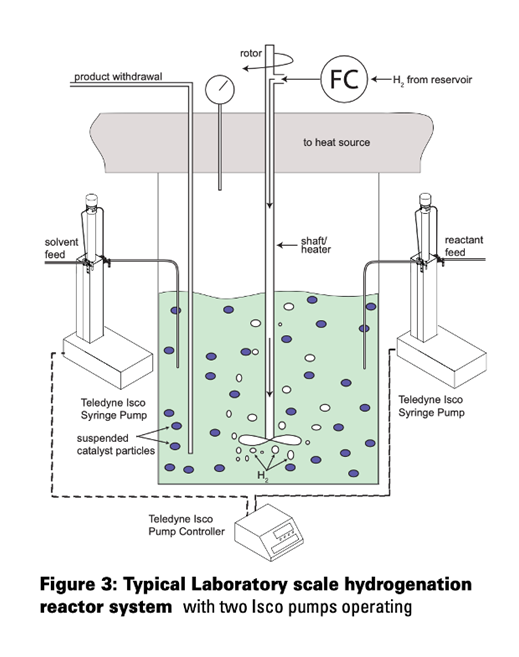

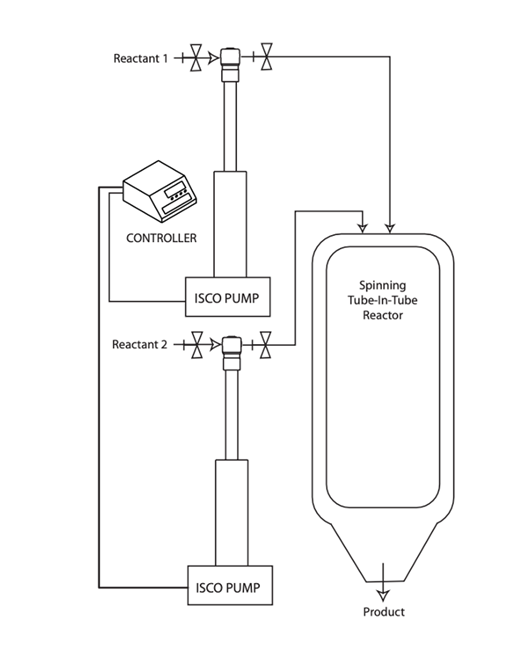

The Teledyne Isco syringe pumps pro- vide precise and accurate flow rates at a precision of 0.5% or better of setpoint over the reaction pressures of 50 to 2000 psi or higher.

Teledyne Isco high precision syringe pumps have been invaluable to this work in demonstrating organic chem- istries in the Spinning Tube-In-Tube (STT®) reactor.

Since the measure of gas dissolved in the polymer melt governs the cell morphology, accurate control of the amount of gas injected into the barrel is the most critical element in the process.

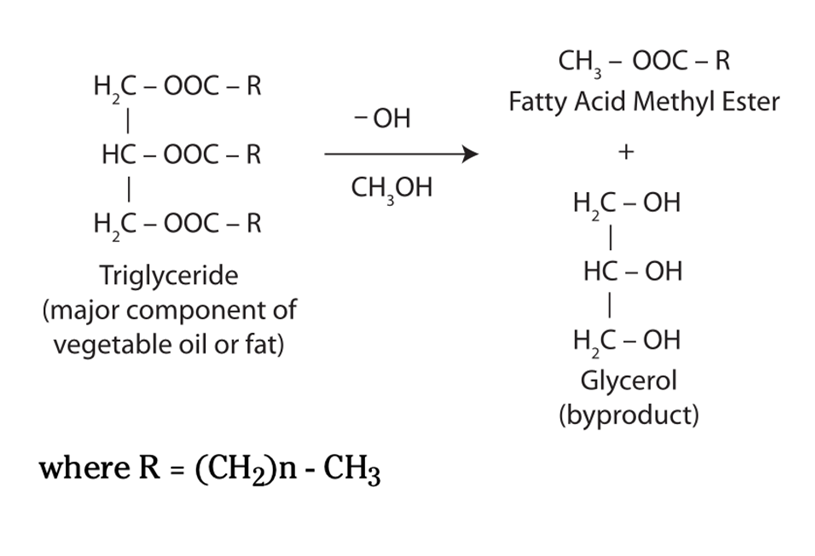

Exploring New Energy Concepts Using Teledyne Isco Syringe Pumps

Teledyne Isco Syringe Pumps are an excellent tool for development of alterna- tive fuels, from bench scale to pilot plant.