Slurry Mixer Using Taledyne Isco Syringe Pumps

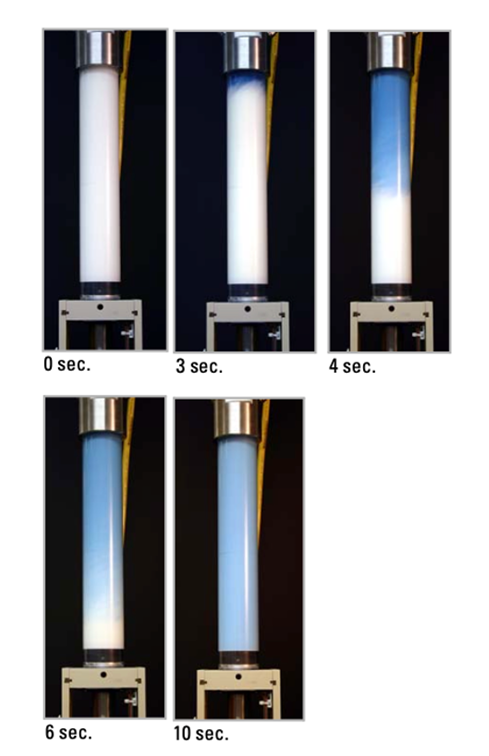

Experiment 1: Distribution

A 20% weight-weight combination of cornstarch and water was drawn into the syringe pump cylinder and mixed with the slurry mixer apparatus.

With the mixture in suspension, 1 mL of blue dye was injected into the inlet port, and the slurry mixer turned on. Total distribution was achieved in under eleven sec- onds, as seen in Figure 4.

Experiment 2: Suspension

The purpose of this experiment was to observe the duration and particle suspension of each solution throughout the length of the pump cylinder, over the duration of a full pumping cycle, the goal being to main- tain a homogeneous mix from the top of the cylinder to the bottom.

Results

The results confirmed that the homogeneity of the slurry was not sustainable for an adequate time without running the slurry mixer to maintain particle suspen- sion. The cornstarch in the slurry mixture settled over time, separating from the water so that the mixture was no longer evenly distributed, while the Isco slurry mixer package maintained even particle suspension over the same amount of time, as seen in Figure 5.